Equipment for Food Fortification and Food Production

We supply specialized food fortification equipment and broader food processing machinery, ensuring safe, efficient, and scalable operations:

WHAT WE SUPPLY

Fortification Hardware

From subtle essentials to high-precision equipment, we provide a comprehensive range of tools that deliver nutrients and verify their presence with accuracy:

Dose: screw and auger feeders keep inclusion rates on-spec

Blend: gentle ribbon or paddle mixers give uniform coverage

Verify: portable test kits and inline samplers confirm every batch

Why it matters: accurate dosing and quick QC mean less waste, faster regulatory sign-off and a tighter nutrient tolerance, even on small or variable lines.

Core Production Machinery

Processing Equipment

Turn raw crops into a fortifiable base and finished product: cleaners, mills and de-hullers, plus extruders and in-line mixers sized to your throughput.

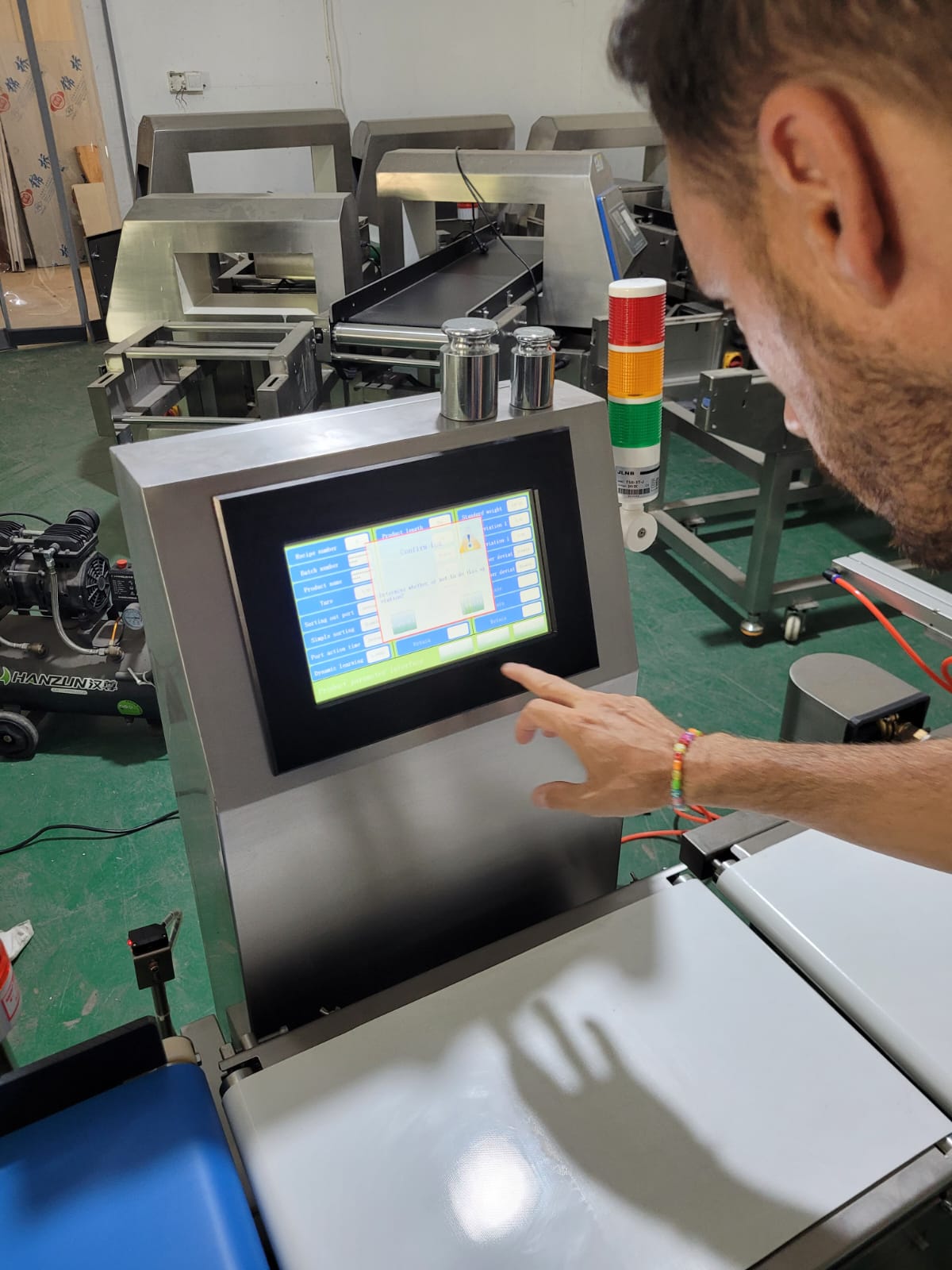

Screening, Sorting & Separation

Keep defects and hazards out: screeners/sifters, magnets,metal detectors and X-ray at critical control points.

Packaging & Post-Processing

Lock quality to the last kilometre: packing lines, precision check-weighers, labellers and traceability options.

Why it matters: a balanced line avoids bottlenecks, preserves nutrient potency and provides the food-safety evidence buyers and auditors expect.

INTEGRATION SUPPORT

Seamless fit, zero guess‑work. Share your layout and throughput; we model footprint, utilities (kW, air, steam), and line balance to ensure each machine – whether fortification‑specific or core processing – lands exactly where it must with the right screw‑pitch, belt speed or residence time. Our team then supervises FAT, instalment, SAT and operator training on‑site

Not sure which grinder, extruder or doser fits your budget and floor‑space?

Share your Process Flow Diagram (PFD), we review it and return a no‑obligation layout, utility list and CAPEX estimate in 72 hours.